Mitigate Supply Chain Disruption with Acumatica Cloud ERP

Digital Strategies for Modern Supply Chains

Proactively Manage Supply Chain Issues

Supply chain issues are nothing new. In 2005, Hurricane Katrina made it impossible for container ships to access Gulf Coast ports. In 2015, Turkish forces shot down a Russian jet resulting in Russia’s blockade of more than a thousand cargo ships. More recently, the global pandemic, Suez Canal blockage, and geopolitical unrest have impacted retail, distribution, construction, and manufacturing supply chains.

Larger businesses with emergency plans and financial resources are more resilient and better-equipped to weather supply chain issues. Conversely, small and midsize businesses struggle to adapt to disruptive events resulting in loss of revenue, market share erosion, and increased costs.

Small businesses are evening the playing field with modern business process automation technologies for demand planning and procurement. Future-proof ERP applications like Acumatica provide breadth and depth with a suite of connected applications providing real-time insights with robust analytics for increased supply chain visibility.

This playbook provides business leaders with an overview of crucial business application features to perfect their supply chains. Learn how to implement inventory strategies for supply and demand transparency. Discover how to overcome supply chain challenges with a scalable and affordable cloud platform designed for growing businesses.

Introduction: Supply Chain Fundamentals

Balancing supply and demand is challenging. Supply chain disruption complicates matters further with many unknown elements. On the one hand, businesses minimize inventory to reduce carrying costs, maximize available warehouse space, and reduce dead stock. However, supply chain issues often force companies to buy excessive inventory to avoid stock-outs that impact sales, production, construction jobs, service appointments, and projects.

“Full supply chain visibility will enable us to target the areas where we have issues and tackle them, to ensure we are operating efficiently and driving growth across sales, supply chain, manufacturing, and finance… we’re also looking to do direct integrations with suppliers, with vendors, and potentially with international partners, which we believe we will be able to do with Acumatica.”

Derek Szabo, Managing Director, Devil’s Peak Brewing Company

A 2021 survey by the U.S. Census Bureau suggests that manufacturing, construction, retail and wholesale trade, and food services currently experience the worst disruption of all industry segments. Further, a recent report by McKinsey notes that companies can expect ten years of supply chain disruptions to erase half a year’s worth of profits.

The pandemic’s supply chain disruption improved gradually since its peak in early 2022. However, experts are cautiously watching for another, more brutal wave of COVID-19 that could have a more devastating impact on supply chains than before. The pandemic’s impact on supply chains hit every sector of the economy. For example, recent lumber shortages in construction coupled with a booming home building market saw lumber prices soar to more than $1,700 per thousand board feet, increasing from $7,000 pre-pandemic to $27,000 during the pandemic peak. A report by Ernst and Young in 2021 revealed that 72 percent of businesses surveyed about the pandemic reported a negative impact on their business compared to just 28 percent that said there was no impact or a positive impact.

With 80 percent of supply chain disruptions originating in downstream suppliers, it is impossible to avoid disruption altogether. Hence, business executives question how to minimize supply chain disruption by implementing systems, processes, and strategies to understand demand better, while protecting vital supply lines for critical products.

Demand: Demand Planning Components and Strategies

Effective supply chains start with demand planning. Without it, businesses cannot develop supply-side strategies. There are two types of demand–actual demand from real orders and forecasted demand from sales projections and statistical forecast models.

“Because we didn’t realize we already had something in another warehouse, we would buy things we didn’t need and carry excess inventory… we’ve really taken the human element out of things like special pricing and leaned on the Acumatica system, which has paid a lot of dividends. It’s made my life a whole lot easier.”

Brett Davis, Operations Manager, Bob Davis Sales

Sales Orders

Orders created by sales reps, blanket contracts, and EDI purchase orders represent real demand, now and in the future. You should look for ways to improve sales processes to minimize supply disruptions.

How Acumatica helps:

- Matrix Items: Use matrix items to create sales orders using item attributes for improved product accuracy.

- Item Photos: Upload item photos to improve order accuracy for in-house sales and customers via connected storefronts.

- Item Categories: Group items by category to make better product identification with default values by item class.

- Substitute Items: Avoid stock-outs with substitute item suggestions

- Stock Allocation: Reserve stock for customer orders from sales order entry.

- Returns and Exchanges: Process RMAs for customers with options for account credit, refund, or exchange with reason codes.

- Pricing and Discounts: Setup customer price sheets and discounts to encourage volume purchases and orders during off-peak times.

- Blanket Sales Orders: Secure long-term commitments with blanket sales orders.

- Order History: Review sales history to improve repeat order accuracy.

- Drop-Shipments: Create vendor purchase orders tagged to the sales order to drop-ship products from suppliers directly to customers.

- Embedded CRM: Gain 360-degree view of customer interactions from a single screen with the embedded CRM with robust service and support applications to manage issues.

- Intercompany Transactions: Automatically create a sales order in one company from a purchase order in another company. Cross-company transactions generate the purchase receipt in the buying company from the shipment in the selling entity and create the sales invoice in the selling company when the bill is created in the buying company.

- Automation: Automate hand-offs to the warehouse, fulfillment partners, construction teams, project managers, service executives, and production for faster order processing.

Inventory Management

Accurate inventory is fundamental for demand planning. Know what you have with visibility into stock status across warehouse locations.

How Acumatica helps:

- Warehouse transfers: Establish replenishment profiles to understand how planned transfer orders impact stock at each warehouse location.

- Kitting: Sales for kits provide visibility into demand for kit components.

- Item Class Hierarchy: Set defaults for sales orders using Item Class Hierarchy definitions to improve data accuracy.

- Dead Stock: Inquiries provide insights into old stock that should be removed from inventory.

- Quality Management: Connected quality management helps identify suspect inventory so it can be isolated from on-hand calculations with corrective actions.

Retail and Commerce

Disconnected point of sale and commerce applications limit demand visibility resulting in inaccurate plans.

How Acumatica helps:

- Native Commerce Connectors: Native commerce connectors synchronize data between Acumatica and storefront apps like BigCommerce and Shopify, ensuring accurate demand planning on a single platform. Certified apps are available for other commerce platforms and marketplaces.

- Embedded Point of Sale: Businesses with showrooms and retail locations use Acumatica Point of Sale for sales connected to inventory and sales order applications.

“With Acumatica, we have a much tighter connection between the sales process flowing to manufacturing, and our inventory accuracy improved substantially.”

Andy Gale, CFO & COO, Liveview Technologies

Other Demand Sources

Connect data from manufacturing, construction, service management, and project accounting for a 360-degree view of demand:

- Manufacturing: Use the MRP application to manage dependent components and raw material demand for finished goods.

- Construction Jobs: Manage demand for materials needed for jobs with the Acumatica Construction Edition.

- Service Management: Account for inventory requirements on service orders with the native service management application.

- Project Accounting: Identify inventory demand from project accounting.

Demand Forecasting

Historical data drives forecasts for improved demand planning.

How Acumatica helps:

- Native Demand Planning: Acumatica supports lead times, safety stock, economic order quantities, min/max, reorder points, moving average forecasts, seasonality, and other replenishment options.

- Connected Demand Forecasting: Certified apps like EazyStock and NetStock provide advanced statistical demand forecasts.

Supply Management Applications and Strategies

Materials are the cornerstone of wholesale distribution, retail, commerce, construction, and manufacturing operations. Manage vendor relationships with embedded CRM and automate the procurement process with a modern ERP platform.

Acumatica is our one-stop shop for everything from accounting to inventory to sales to purchasing and so on. For technology to work well without hacks or workarounds is rare, and Acumatica works really well.”

Craig Matusinski, eCommerce Director, Kevins Worldwide

Purchasing/Sourcing

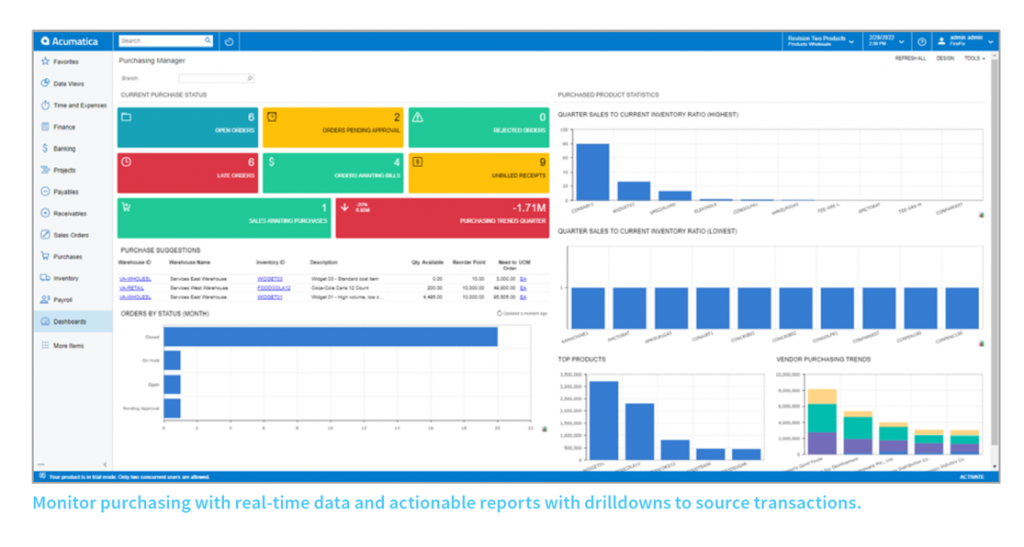

Automate purchase order processes, discover new vendors with native requisitions, implement vendor-managed inventory strategies, and improve supplier relationships with embedded CRM.

How Acumatica helps:

- Vendor Management: Setup vendors with defaults by vendor class. Import vendor product catalogs with price lists and set up vendor contacts and billing details.

- Purchase Orders: Create purchase orders from scratch, copy them from previous orders or templates, or automate them based on stock levels.

- Blanket Orders: Provide vendors with transparency into future demand by setting up blanket orders for long-term contracts.

- Requisitions: Automate vendor bidding and approvals for stock and non-stock items. Email requests to suppliers, digitally collect bids, and convert winning bids directly into vendor records and purchase orders.

- Drop-Shipments: Create vendor purchase orders tagged to the sales order to drop-ship products from suppliers directly to customers.

- Vendor Managed Inventory: Acumatica’s unlimited user licensing and cloud framework empowers vendors to securely monitor inventory levels for products they supply to your organization. Alert vendors of low stock, enabling them to create purchase orders in Acumatica for buyer approval.

- Consigned Inventory: Acumatica’s cloud framework makes it easy to manage consigned inventory to stock vendor inventory that is not on your financial books until sold or used.

- Intercompany: Automatically create a sales order in one company from a purchase order in another company. Cross-company transactions generate the purchase receipt in the buying company from the shipment in the selling entity and create the sales invoice in the selling company when the bill is created in the buying company.

- Procure-to-pay: Improve vendor relations with procure-to-pay automation powered by artificial intelligence with machine learning.

“The quote to cash cycle is the lifeblood of our business, and Acumatica has given us the tools to manage it effectively and efficiently every step of the way. We have valuable tools to see what is coming, to do all our forecasting through dashboards, and focus on key customers.”

Tim Patton, ICT Director, SAM

Inventory Management

Stock inventory represents immediate supply to fill customer orders. Use existing stock for service appointments, construction jobs, and manufacturing production orders.

How Acumatica helps:

- Vendor Items: Cross-reference internal items using vendor part numbers.

- Inventory: Manage inventory effectively with connected purchasing, sales, production, service, project accounting, construction, and financial applications.

- Kit Disassembly: Return kit components to stock with the kit disassembly activity.

- Physical Inventory: Use the physical inventory app to ensure stock accuracy for improved order management.

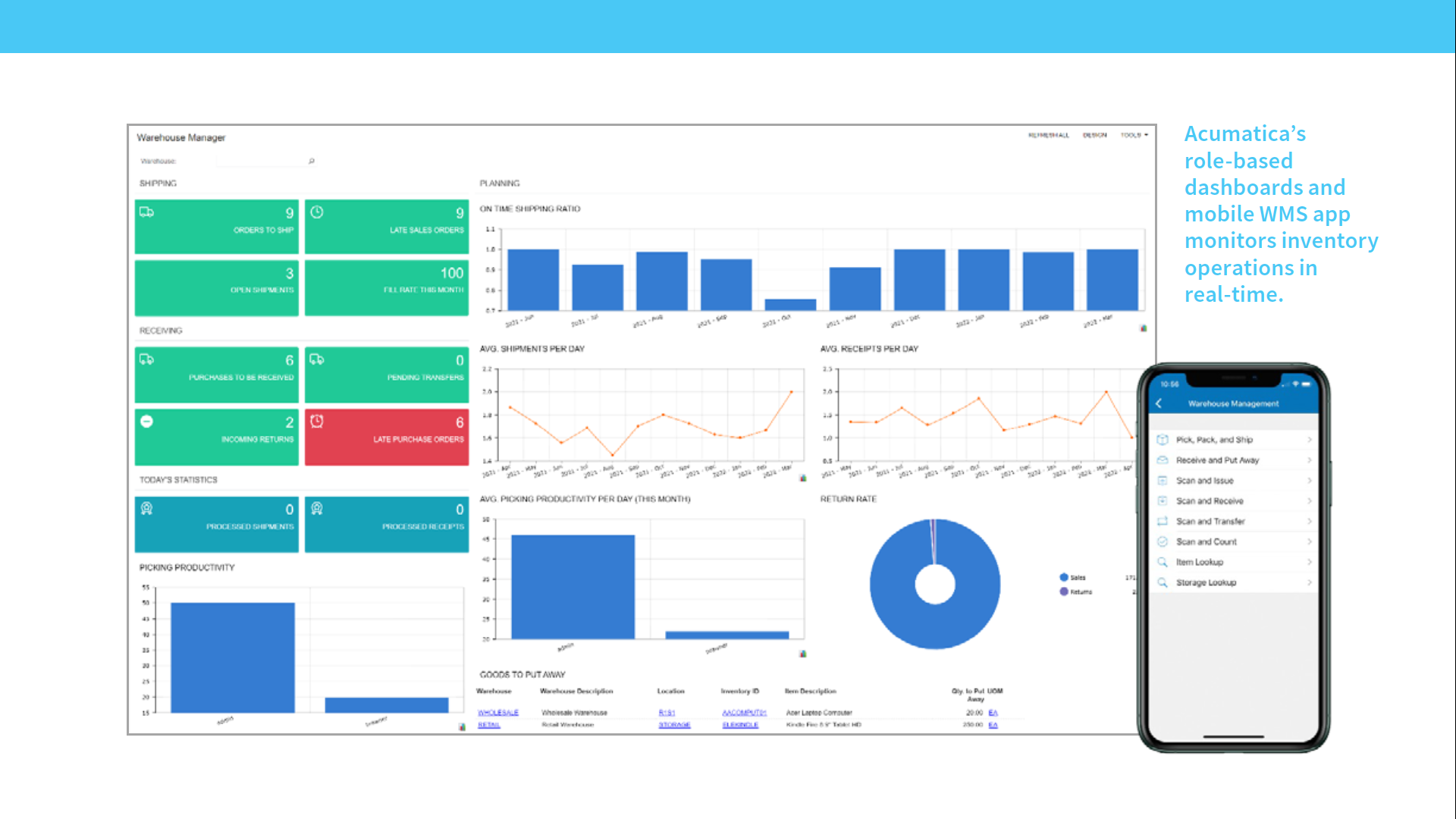

- Warehouse Management: Automate warehouse transactions with the mobile WMS application for receipt, put-away, picking, packing, and shipping, implement paperless picking with prioritized picking queues and batch and wave picking.

- Replenishment: Acumatica supports lead times, safety stock, economic order quantities, min/max, reorder points, moving average forecasts, seasonality, and more.

- Warehouse Transfers: Set up replenishment profiles between locations to understand how planned transfer orders increase supply at each warehouse.

Other Supply Applications

Manage other supply sources with Acumatica manufacturing and returns. Foster supplier relationships with embedded CRM and extend Acumatica with certified applications.

How Acumatica helps:

- Manufacturing: Acumatica supports make-to-stock, make-to-order, batch process, and project-centric manufacturers with connected applications for production, estimating, engineering, material planning, scheduling, and product configuration.

- Returns: Process customer returns into inventory for future order fulfillment or product disposition.

- Embedded CRM: Setup vendors in Acumatica’s native CRM applications for a 360-degree view of supplier contacts, communication, and information with support cases to manage issues.

- Quality Management: The certified eWorkplace Apps quality module supports quality testing and reporting to minimize returns and boost customer satisfaction.

- Advanced AP/PO Automation: Acumatica’s extensive marketplace includes apps like SourceDay for advanced supply chain and vendor management.

- Electronic Data Interchange: Expedite vendor purchase orders and receive advance ship notices with certified EDI apps.

“By tracking and authenticating asset movement in the supply chain and in the warehouse through use of technologies such as RFID and blockchain, order verification is automated, minimizing errors and our customers can have much more confidence that the goods they’re purchasing are authentic, not counterfeit.”

Bluefin Collectibles

Advanced Supply Chain Strategies

Technology alone cannot solve every supply chain problem. Creative thinking and innovation often produce tremendous results to mitigate supply chain risks. Below are ideas to elevate your supply chain management strategy.

- Digital Transformation: Implement a modern ERP system with tools to improve vendor transparency.

- Improve Data: Implement physical inventory with barcode scanning, artificial intelligence, and statistical forecasts to improve data for planning. Capture vendor performance for insights into quality issues and lead times. Use data to reduce carrying costs by targeting popular items with higher profits.

- Adjust Strategies: Consider smaller recurring orders from multiple vendors or buy less often in larger quantities. Adjust safety stock levels to buffer late deliveries and implement vendor-managed and consigned inventory for increased collaboration.

- Expand Capabilities: Distributors and retailers may add kitting or additive manufacturing to make products they source today. Consider adding refurbishment and recycling services to source and repair hard-to-find items from obsolete products.

- Diversify Suppliers: Use requisitions to solicit bids from new suppliers, add onshore vendors for items you currently source overseas, and ask vendors if they can supply other products to diversify your vendor network. Also, consider working with multiple transportation providers for more flexibility.

- Eliminate Bottlenecks: Consider drop-shipments from vendors directly to customers and go directly to source suppliers. Acquire strategic suppliers and consider locations closer to customers or suppliers to reduce transportation costs and lead times.

- Make Investments: Invest in employees to avoid labor shortages, skills training to empower employees with knowledge, systems to automate processes, and business process improvement to eradicate waste. Invest in research and development to make products that are problematic to source elsewhere.

Strategic Supply Chain Management with Acumatica Cloud ERP

Without the right business systems, supply chain management is challenging to automate processes, manage issues, and work collaboratively with customers and vendors.

Acumatica provides a holistic and modern ERP platform for small and growing inventory-centric businesses to mitigate supply chain disruption. The robust distribution suite includes embedded warehouse management capabilities, flexible replenishment features, and powerful purchasing tools like purchase order requisitions with vendor bidding that are uncommon in midmarket ERP applications.

Supply chain features flow across the Acumatica system connecting inventory, sales, retail, commerce, construction, service, project, and manufacturing transactions for a real-time consolidated view of demand across the organization. Certified marketplace applications extend Acumatica with advanced options to further automate and improve supply chain plans.

Acumatica provides everything that progressive manufacturers need to effectively manage internal systems and processes. Improve planning and reduce cycle times with best-in-class applications for production, estimating, engineering, material planning, scheduling, product configuration, and manufacturing data collection. Acumatica is design for make-to-stock, make-to-order, configure-to-order, engineer-to-order, repetitive, and project-centric manufacturers.